Textron and the Environment

Textron understands its responsibility to participate in working toward a sustainable future for the environment. Our responsibility to the environment starts with our compliance with regulatory requirements and is supported by our Textron Global EHS Policies and Standards which we follow in all countries where we operate. Beyond compliance, we are focused on reducing the energy and natural resource intensity of our operations and contributing positively to the communities in which we operate.

SUSTAINABLE FOOTPRINT

ACHIEVE 2025 SUSTAINABLE FOOTPRINT GOALS

In 2020 as part of our Achieve 2025 initiative, we established a new set of 5-year sustainability goals specific to the following areas of focus: greenhouse gas emissions, energy use, water use and waste generation. By 2025, Textron’s business will strive to achieve the following goals:

- Reduce greenhouse gas emission intensity by 20%;

- Reduce energy use intensity by 10%;

- Reduce water use intensity by 10%, and;

- Reduce waste generation intensity by 10%.

These goals were developed with the intent to create a company that will be more efficient in its use of natural resources to meet the expectations of our customers, shareholders, employees and other stakeholders to better the communities in which our businesses operate. An added benefit of the Achieve 2025 Sustainable Footprint goals will be economic savings due to more efficient operations.

To achieve these goals by 2025, Textron intends to work with our suppliers to carry out resource improvement projects at our facilities and continuously look for more efficient methods in our energy procurement and manufacturing processes. As a demonstration of this commitment, Textron has joined the Renewable Energy Buyers Alliance (REBA). REBA is an alliance of large clean energy buyers, energy providers, and service providers that, together with NGO partners, are working to support access to renewable energy and the greening of the power grid.

TEXTRON’S 2020 SUSTAINABILITY PROJECTS: REDUCING OUR ENVIRONMENTAL FOOTPRINT

In 2020 Textron operations around the globe were able to complete 145 sustainability projects aimed at energy, waste or water use reduction. In addition to saving Textron over $2 million, these projects helped Textron improve by increasing energy efficiency and reducing greenhouse gas emissions, water use and waste generation. Project savings on energy were over 40,000 mmBTUs, which resulted in reducing greenhouse gas emissions by over 5,500 metric tons. Our waste minimization efforts helped to reduce our landfill disposal by almost 3,400,000 pounds. Water projects resulted in approximately 1.7 million gallons of water savings.

2020 SUSTAINABILITY PERFORMANCE

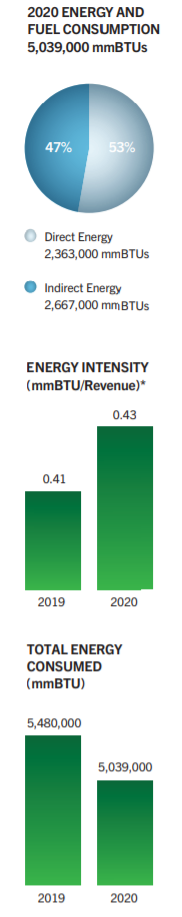

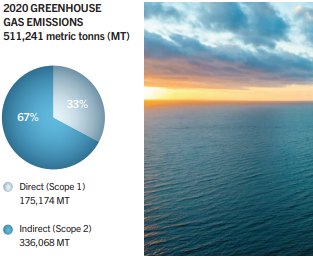

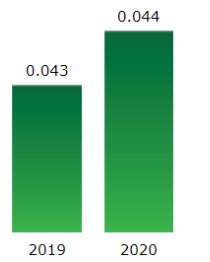

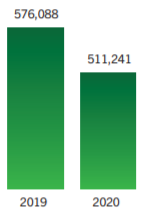

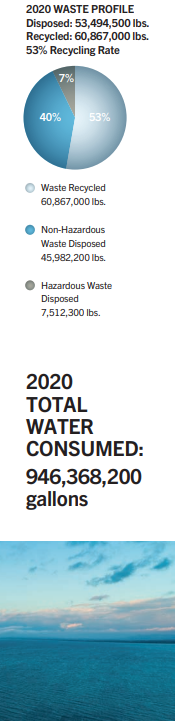

The charts that follow show our 2020 energy consumption and greenhouse gas emissions data compared to 2019, as well as our 2020 waste profile and water consumption. Due to COVID-19-related business interruptions that impacted 2020 intensity values, for this year’s version of the Corporate Responsibility Report, we have provided energy consumption and greenhouse gas emission data in both absolute values and intensity-based figures.

ENERGY CONSUMPTION

GREENHOUSE GAS (GHG) EMISSIONS

Greenhouse gas (GHG) emissions are determined following the Greenhouse Gas Protocols of the World Business Council for Sustainable Development and the World Resource Institute. Consistent with these protocols, Textron accounts for direct (Scope 1) and indirect (Scope 2) GHG emissions in terms of CO2 -equivalents. Our greenhouse gas emissions and calculation methodology have been verified by an ANSI-accredited independent third party in accordance with ISO 14064-3.

WASTE MINIMALIZATION AND RECYCLING

*Intensity metrics are normalized to revenue.

ENVIRONMENTAL IMPROVEMENT HIGHLIGHTS

TEXTRON AVIATION OFFSETTING CARBON EMISSIONS WITH WIND ENERGY

As demonstrated by our 5-year Achieve 2025 Energy Use and Greenhouse Gas Emission reduction goals, we are committed to creating more efficient operations and reducing greenhouse gas emissions from our manufacturing operations. While more efficient use of energy will help make progress toward meeting our greenhouse gas emission reduction goal, to fully achieve that goal, we will need to procure and consume energy that is generated in more environmentally friendly manners than some of our current sources.

In November 2020, construction of the 121 turbine, 300 Megawatt Soldier Creek Wind Energy Center located in rural north-central Kansas was completed and the facility began generating clean, renewable electricity. Through a 20-year agreement with Evergy, Inc., the developer of the Soldier Creek Wind Energy Center, the electricity used by Textron Aviation’s aircraft manufacturing operations located in Kansas will be provided through Evergy’s green energy program, effectively meeting nearly all of these electricity needs through renewable, zero-emission wind energy. This exciting development will result in approximately 100,000 metric tons of greenhouse gas emissions being avoided on an annual basis and make a significant amount of progress toward our Achieve 2025 Greenhouse Gas Emission goal.

TEXTRON AVIATION’S SERVICE CENTER REDUCES ENERGY CONSUMPTION AND COSTS WITH LED LIGHTING

A Textron Aviation lighting system consisting of nearly 200 metal halide fixtures in the Greensboro, N.C., service center was replaced with an LED system. More than 100 LEDs now light the full-service center which provides modifications and repairs for Citation, King Air, Beechjet, Premier and Hawker aircraft.

As a programmable system, it aids in managing lighting levels and reduces energy consumption. The changeover to LED lighting resulted in average monthly savings of approximately $1,900 and a reduction in total energy costs and consumption of 30 percent. The new system paid for itself in 19 months. In addition to these savings, LED lighting decreases the number of required headlamps and lessens the need for paint rework.

KAUTEX FACILITIES REDUCE SCRAP, REPURPOSE EQUIPMENT

Kautex’s 0-0-0 initiative—the drive to achieve zero scrap, zero unplanned downtime and zero injuries—has generated improvements, including more sustainable manufacturing practices, increased productivity and safer workspaces.

Of particular note is a project that a team at the Kautex facility in Guangzhou, China undertook to reduce scrap in its fuel tank manufacturing process. Its three-pronged approach incorporated technology and new processes to reduce the scrap rate and decrease the contamination scrap. With these measures in place, the facility has been able to more efficiently use its materials, translating to waste avoidance equivalent to 7,490 kg/year.

At its facility in Avilla, Indiana, the Kautex team won an internal Vision 2025 award in the R3 category—Refurbish, Rebuild, Repurpose. Eighty-eight percent of all equipment used for quoted projects in 2020 was reused. The total value of all re-used equipment used in 2020 was $260 million.

KANSAS FARMERS HELP MANAGE TEXTRON AVIATION GRASSLAND

Textron Aviation, which has called Kansas home since Cessna was founded in 1927 and Beechcraft in 1932, proudly works with local Kansas farmers to cut and bale hay on the company property. Almost 1,000 acres of Textron Aviation grassland is utilized for hay production.

Hay is grown without chemical fertilizers, pesticides or herbicides. Grassland and vegetation prevent soil erosion by reducing water runoff and stabilizing the soil. Research shows that natural grasslands promote biodiversity and pollination. By letting the grass grow free and only cutting for baling instead of mowing for maintenance, natural plants and flowers thrive.

What’s more, by not maintaining the almost 1,000 acres of property as a manicured lawn, Textron Aviation avoids water waste and reduces resource inputs that go into mowing and caring for a traditional lawn.

Embracing responsible land management helps connect Textron Aviation with the agricultural fabric of the company’s home state and is an important part of the company’s comprehensive commitment to sustainability.

BELL BECOMES FIRST ROTORCRAFT CUSTOMER TO USE SUSTAINABLE AVIATION FUEL FOR TRAINING

Bell has begun incorporating Sustainable Aviation Fuel (SAF) into all Bell Training Academy and customer demonstration fleet aircraft. Bell is the first rotorcraft customer to receive SAF supply from global aviation fuel supplier, Avfuel Corporation. As an active supporter of the General Aviation Manufacturers Association’s sustainable fuel initiative, Bell is committed to seeking more eco-friendly solutions for rotorcraft. The industry is moving toward a greener future, and introducing SAF in our training and demonstration aircraft reflects our dedication to this shared goal and to providing clean alternatives for the environment. Bell continues to support the aviation industry in its objectives to achieve carbon neutral growth and reduce CO2 emissions by 50% by 2050.